Product Description

Material Composition: HSS Gear Hob Cutters are primarily crafted from high-speed steel, renowned for its exceptional heat resistance, hardness, and toughness.

Precision Cutting Profiles: These cutters are meticulously engineered with specific tooth profiles aligned with gear standards (such as involute, cycloidal, etc.). This precision ensures accurate gear tooth shapes and sizes across various gear modules and configurations.

Versatility in Materials: HSS Gear Hob Cutters are capable of cutting gear teeth in a wide range of materials. They efficiently work on various metals including steel, stainless steel, aluminum, brass, copper, and different alloys.

Variety of Sizes and Configurations: Available in different dimensions including diameters, widths, tooth numbers, and configurations, enabling them to cater to diverse gear modules and design requirements.

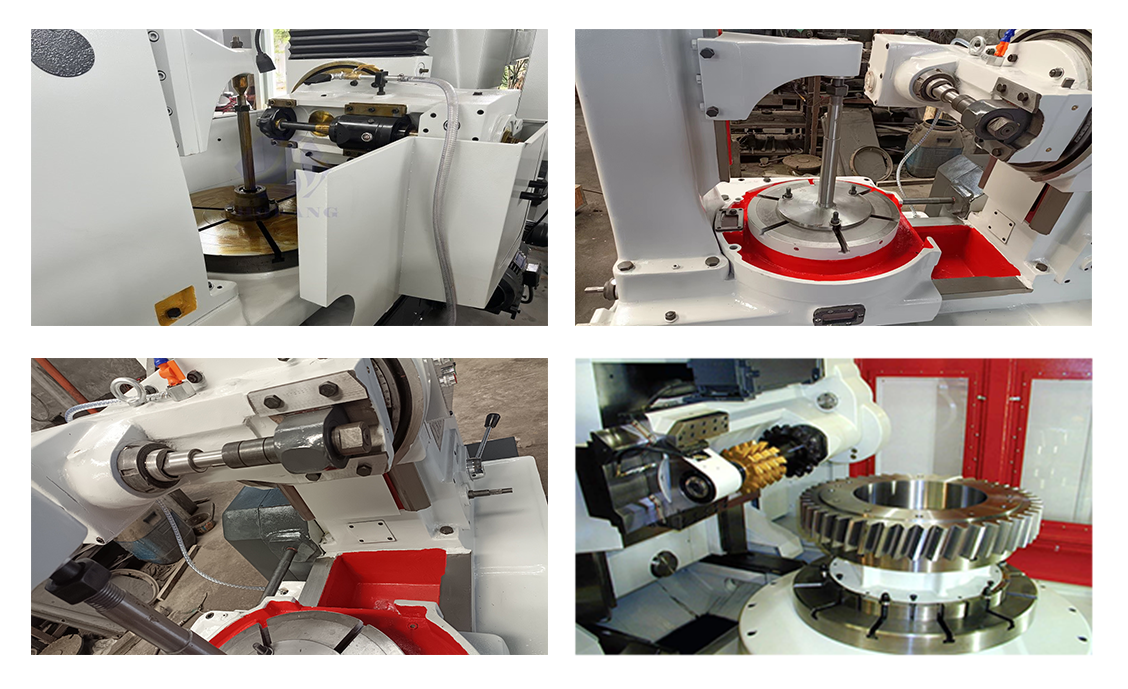

Compatibility and Usage: These cutters are used on specialized gear hobbing machines dedicated to gear cutting operations. Proper setup, alignment, and adherence to recommended cutting parameters such as speeds, feeds, and lubrication are vital for efficient and precise cutting.

Durability and Wear Resistance: HSS provides good wear resistance and durability, allowing these cutters to maintain their cutting effectiveness and sharpness under appropriate cutting conditions.

Potential for Resharpening: Depending on wear and condition, some HSS Gear Hob Cutters can be resharpened or reconditioned, prolonging their usable life and reducing replacement frequency.

Maintenance and Surface Treatments: Regular maintenance is crucial to retain optimal performance. Some cutters may have specialized surface coatings or treatments to enhance cutting efficiency, minimize friction, and extend tool life.

Documentation and Support: Manufacturers provide technical specifications, operational guidelines, and maintenance instructions with these cutters. They may also offer technical support or expertise for optimal usage and troubleshooting.

Material Composition: Crafted primarily from high-speed steel known for its exceptional hardness, toughness, and heat resistance.

Purpose: Specifically designed for precise cutting of gear teeth in various materials, including ferrous metals (steel, stainless steel), non-ferrous metals (aluminum, brass), and plastics used in gear manufacturing.

Cutting Profiles: Engineered with accurate tooth profiles aligned with gear standards (like involute, cycloidal) to create precise gear tooth shapes and sizes across different gear modules and configurations.

Variety of Sizes: Available in different dimensions including diameters, widths, tooth numbers, and configurations to cater to diverse gear module sizes and gear designs.

Compatibility and Usage: Used on specialized gear hobbing machines for dedicated gear cutting operations, requiring proper setup, alignment, and adherence to recommended cutting parameters for efficiency and accuracy.

Durability and Wear Resistance: Exhibits good wear resistance and durability under appropriate cutting conditions, maintaining cutting effectiveness and sharpness.

Potential for Resharpening: Depending on wear and condition, some HSS Gear Hob Cutters can be resharpened or reconditioned, extending their usable life.

Maintenance and Coatings: Regular maintenance is essential, and some cutters may have specialized coatings or treatments to enhance cutting efficiency and tool longevity.

Model Number:EJTGS-00HN-FOC

Standard:GB, DIN, AGMA, BS, and so on

Mateiral:HSS-Co, M2, Carbide, High-quality HSS

Coating:TiN,TiAlN,TiCN,AlCrN and so on

Flute:Straight and helical flute

Type:Consumables used for processing

Heat treatment:64 - 67HRC

Accuracy:DIN-AA

Material Composition: Primarily made from high-speed steel, renowned for its exceptional hardness, heat resistance, and toughness, enabling it to maintain cutting edge sharpness at high speeds.

Cutting Profiles: Engineered with precise tooth profiles aligned with gear standards (like involute, cycloidal) to produce accurate gear tooth shapes and sizes across various gear modules and configurations.

Material Versatility: Capable of cutting gear teeth in diverse materials, including ferrous metals (steel, stainless steel), non-ferrous metals (aluminum, brass), and plastics commonly used in gear manufacturing.

Sizes and Configurations: Available in various dimensions such as diameters, widths, tooth numbers, and configurations, accommodating different gear module sizes and designs.

Usage on Gear Hobbing Machines: Used on specialized gear hobbing machines dedicated to gear cutting operations. Proper setup, alignment, and adherence to recommended cutting parameters (speeds, feeds, lubrication) are essential for precision cutting.

Durability and Wear Resistance: Exhibits good wear resistance and durability under appropriate cutting conditions, maintaining cutting effectiveness and edge sharpness.

Potential for Resharpening: Depending on wear and condition, some HSS Gear Hob Cutters can be resharpened or reconditioned, extending their service life.

Maintenance and Surface Treatments: Regular maintenance is crucial for optimal performance. Some cutters may have specialized coatings or treatments to enhance cutting efficiency and tool longevity.

Documentation and Technical Support: Manufacturers provide technical specifications, operational guidelines, and maintenance instructions. Technical support may also be available for optimal usage and troubleshooting.

Personal Protective Equipment (PPE): Always wear appropriate PPE such as safety goggles, gloves, and hearing protection. This protects against potential hazards like metal chips, debris, and noise during cutting operations.

Proper Handling: Handle HSS Gear Hob Cutters with care to avoid damage to the cutting edges or critical parts. Improper handling may lead to tool damage or potential hazards.

Compatibility and Setup: Ensure proper compatibility between the cutter and gear hobbing machine. Improper setup, alignment, or mounting may cause malfunction, breakage, or accidents.

Adherence to Cutting Parameters: Always follow manufacturer-recommended cutting speeds, feeds, depths of cut, and use suitable coolants/lubricants. Deviating from guidelines may affect performance or cause tool breakage.

Regular Inspection: Before use, inspect the cutter for damage, wear, or dullness. Using a damaged or worn cutter can compromise cutting quality or cause tool failure during operation.

Avoid Excessive Force: Do not apply excessive pressure while cutting. Let the cutter and machine perform the work to prevent overheating, premature wear, or breakage.

Resharpening and Maintenance: Entrust resharpening or reconditioning to experts as needed. Attempting to sharpen or modify the cutter without expertise can lead to damage or unsafe conditions.

Operator Training: Ensure operators handling HSS Gear Hob Cutters are adequately trained in setup, operation, and safety procedures. Lack of expertise may lead to accidents or improper tool usage.

Emergency Response Preparedness: Establish emergency response protocols in case of accidents or tool failure during operations. Provide access to first aid and emergency shutdown procedures.

Manufacturer Guidelines: Always refer to the manufacturer's instructions, warnings, and guidelines provided with the cutter for specific safety instructions and precautions.

What is an HSS Gear Hob Cutter?

An HSS Gear Hob Cutter is a specialized cutting tool designed for shaping gear teeth accurately in various materials, made from high-speed steel known for its durability and heat resistance.

Which materials can HSS Gear Hob Cutters work on?

These cutters are suitable for cutting gear teeth in diverse materials, including ferrous metals (steel, stainless steel), non-ferrous metals (aluminum, brass), and plastics commonly used in gear manufacturing.

What types of gear profiles can HSS Gear Hob Cutters produce?

HSS Gear Hob Cutters are engineered with precise tooth profiles aligned with gear standards (e.g., involute, cycloidal) to create accurate gear tooth shapes and sizes across different gear modules and configurations.

Are there different sizes available for HSS Gear Hob Cutters?

Yes, these cutters are available in various dimensions including diameters, widths, tooth numbers, and configurations to cater to different gear module sizes and designs.

How are HSS Gear Hob Cutters used?

They are used on specialized gear hobbing machines dedicated to gear cutting operations. Proper setup, alignment, and adherence to recommended cutting parameters (speeds, feeds, lubrication) are essential for efficient and accurate cutting.

Can HSS Gear Hob Cutters be resharpened or reconditioned?

Depending on wear and condition, some HSS Gear Hob Cutters can be resharpened or reconditioned by specialized tooling companies, extending their service life.

What safety precautions should be taken when using HSS Gear Hob Cutters?

Always wear appropriate personal protective equipment (PPE), follow recommended cutting parameters, inspect the cutter for damage before use, avoid excessive force, and seek professional help for cutter maintenance or resharpening.

Are there specific maintenance guidelines for HSS Gear Hob Cutters?

Yes, manufacturers provide maintenance instructions for handling, storage, and inspection of the cutter. Regular inspection and proper handling are crucial for maintaining cutter performance and longevity.

Can HSS Gear Hob Cutters be customized for specific gear cutting requirements?

Some manufacturers may offer customization options for tooth profiles, dimensions, coatings, or other specifications to meet unique gear manufacturing needs.

Where can I find technical information and guidelines for using HSS Gear Hob Cutters?

Technical specifications, operational guidelines, and maintenance instructions are typically provided by the manufacturer along with the cutter. Refer to these documents for specific details and guidelines.