EJ/Customized

Metal

EJ/Customized

Manufacturing Plant, Construction works

| Availability: | |

|---|---|

| Quantity: | |

Product Description

Hobbing Process: Gear hobbing machines employ a hob—a cutting tool—to generate gears by cutting teeth into a workpiece.

Accuracy: These machines offer high precision, ensuring the creation of gears with accurate tooth profiles and dimensions.

Versatility: They can produce a variety of gears, including spur gears, helical gears, worm gears, and more, offering flexibility in gear production.

Cutting Capabilities: Gear hobbing machines are capable of both generating (producing gears with specific tooth profiles) and finishing (achieving precise dimensions and surface finish) operations.

Automation: Many modern machines feature automation and CNC controls for improved efficiency, allowing for complex gear profiles and reducing manual labor.

Tooling Options: These machines accommodate various types and sizes of hobs, enabling the production of gears of different sizes and specifications.

Feed and Speed Control: They provide control over cutting speeds, feeds, and depth of cut, ensuring optimal machining parameters for different materials and gear types.

Coolant Systems: Incorporate coolant systems to manage heat generation during the cutting process, ensuring tool longevity and workpiece quality.

Safety Features: Equipped with safety measures such as interlocks, guards, and emergency stop mechanisms to ensure operator safety during operation.

Maintenance: Designed for ease of maintenance and serviceability to keep the machines running efficiently.

Gear hobbing machine paraments

| Type | Gear Hobbing Machine | Place of Origin | Jiangsu,China |

| Key Selling Points | Automatic | Max Module | 3mm |

| CNC or Not | CNC | Dimension(L*W*H) | 3530*3480*2550mm |

| Rotating angle of Arbor | 45° | Total Power | 30KVA |

| Support customization, welcome to contact us. | |||

Machine Type: Gear hobbing machines can be horizontal or vertical, each with distinct advantages in terms of space, setup, and specific gear production requirements.

Hobbing Capacity: Specifies the maximum diameter and module (or DP - Diametral Pitch) of the gears that the machine can produce.

Number of Axes: Determines the machine's capabilities for multi-axis machining, including the number of axes for hob rotation, axial movement, radial movement, and additional indexing axes for complex gear profiles.

Cutting Speeds and Feeds: Specifies the range of cutting speeds, feed rates, and depth of cut options available to accommodate various materials and gear types.

Control System: Modern gear hobbing machines often feature CNC (Computer Numerical Control) systems for precise control of cutting parameters, gear profiles, and automated operations.

Tooling Options: Details the types and sizes of hobs or cutting tools the machine can accommodate, including the maximum hob dimensions and configurations.

Automation Features: Includes options for automatic loading and unloading of workpieces, tool changing systems, and robotic integration for increased productivity.

Accuracy and Tolerances: Specifies the machine's capabilities in terms of accuracy, repeatability, and achievable gear tolerances.

Coolant Systems: Describes the coolant capacity and effectiveness in managing heat during the machining process to enhance tool life and workpiece quality.

Dimensions and Weight: Provides the machine's physical dimensions, floor space required, and weight for installation and operational considerations.

Max Module:3mm

CNC or Not:CNC

Dimension(L*W*H):3530*3480*2550mm

Max stroke of Y axes:100mm

Max stroke of Z axes:280mm

Rotating angle of Arbor:45°

Total Power:30KV

Purpose: Gear hobbing machines are designed to create gears by cutting teeth into cylindrical workpieces using a hobbing tool.

Types: They come in horizontal and vertical configurations, each suitable for different gear types and production requirements.

Process: Gear hobbing involves rotating the workpiece and the hob simultaneously while feeding the hob axially across the workpiece to generate gear teeth.

Capabilities: These machines produce various gear types such as spur gears, helical gears, splines, worm gears, and more, offering flexibility in gear manufacturing.

Accuracy: Gear hobbing machines ensure high precision and repeatability in gear production, providing accurate tooth profiles and dimensions.

Automation: Modern gear hobbing machines often incorporate CNC controls and automation for improved efficiency, allowing for complex gear profiles and reduced manual intervention.

Tooling: Accommodate different types and sizes of hobs or cutting tools to produce gears of various sizes and specifications.

Coolant Systems: Equipped with coolant systems to manage heat generated during cutting, ensuring tool longevity and workpiece quality.

Versatility: These machines offer versatility in the production of gears for industries like automotive, aerospace, machinery, and more.

Maintenance: Designed for ease of maintenance to keep the machines running efficiently and reliably.

Sharp Cutting Tools: Gear hobbing involves sharp cutting tools that can cause severe injuries. Handle hobs and tools with extreme caution, use appropriate personal protective equipment (PPE), such as gloves and eye protection.

Moving Parts: Gear hobbing machines have rotating components. Avoid wearing loose clothing or jewelry that can get caught in moving parts.

High-Speed Rotations: The rotating workpiece and cutting tools operate at high speeds, posing risks of entanglement and injury. Keep a safe distance and avoid reaching into the machine during operation.

Heat and Coolant: The machining process generates heat. Use caution to prevent burns from contact with hot workpieces or coolant.

Machine Specifics: Understand and follow the machine's specific safety guidelines provided by the manufacturer. Adhere to recommended operating speeds, feeds, and tooling instructions.

Training: Only trained and authorized personnel should operate gear hobbing machines. Proper training in machine operation, safety protocols, and emergency procedures is crucial.

Maintenance: Regularly maintain and inspect the machine to ensure proper functionality and safety measures. Address any issues promptly.

Emergency Stop: Familiarize yourself with the emergency stop features and ensure they are readily accessible in case of any unforeseen circumstances.

Safety Guards: Keep all safety guards and interlocks in place and functional to prevent accidental contact with moving parts.

Lockout/Tagout: Use lockout/tagout procedures when servicing or maintaining the machine to prevent accidental startup.

What is a gear hobbing machine?

A gear hobbing machine is a specialized tool used in the production of gears by cutting teeth into cylindrical workpieces using a hobbing cutter.

What types of gears can be produced with gear hobbing machines?

Gear hobbing machines can produce various types of gears, including spur gears, helical gears, worm gears, splines, and more.

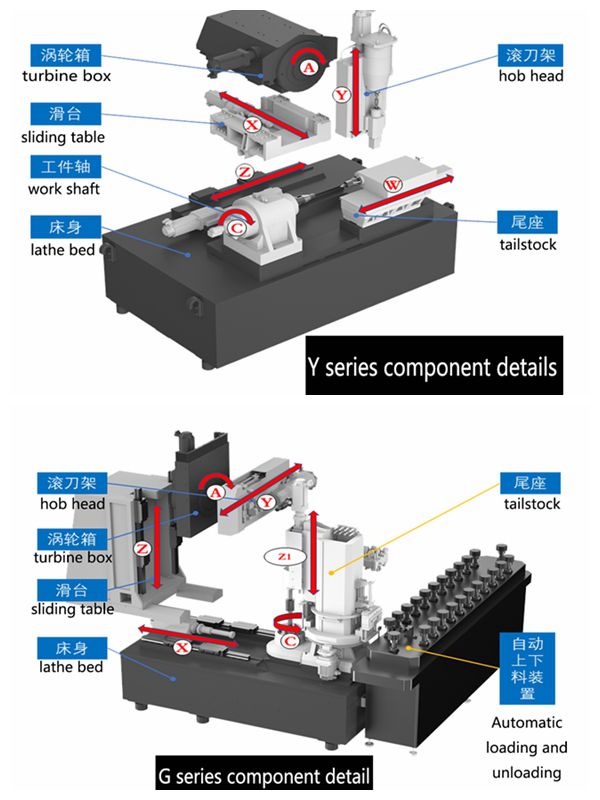

What are the main components of a gear hobbing machine?

Components include the hobbing tool, workpiece spindle, hob spindle, cutting mechanism, feed and speed controls, and in some cases, CNC controls.

What are the advantages of gear hobbing machines?

Gear hobbing machines offer high precision, accuracy, and repeatability in gear production, allowing for the creation of complex gear profiles.

How do gear hobbing machines work?

These machines work by rotating the workpiece and the hob cutter simultaneously while feeding the hob across the workpiece, cutting gear teeth.

What materials can be used in gear hobbing?

Gear hobbing machines can work with various materials such as steel, stainless steel, cast iron, brass, and other alloys used in gear manufacturing.

Are gear hobbing machines automated?

Modern gear hobbing machines often incorporate CNC controls and automation, allowing for precise control and complex gear profile creation.

What safety precautions should be taken when operating gear hobbing machines?

Use proper personal protective equipment (PPE), follow machine-specific safety guidelines, avoid loose clothing, and ensure emergency stops are accessible.

Can gear hobbing machines produce gears of different sizes?

Yes, these machines can produce gears of various sizes and specifications by accommodating different hob sizes and configurations.

Where are gear hobbing machines commonly used?

Gear hobbing machines are used in industries such as automotive, aerospace, machinery manufacturing, and more, for producing gears for various applications.